Phone

+90 232 436 37 42

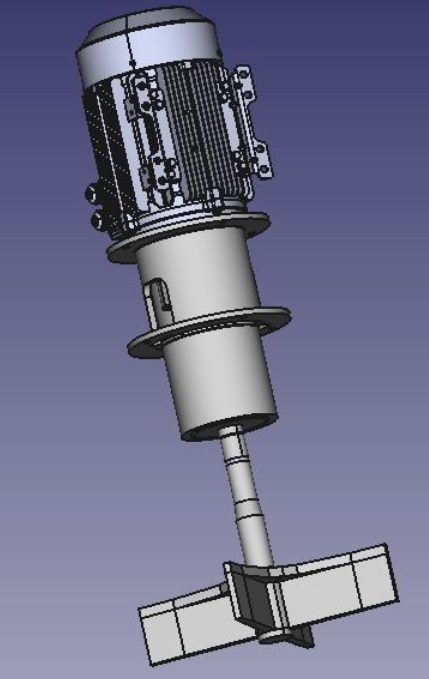

Circulation fan typically used to improve airflow inside the oven

It is installed inside the furnaces. Fans work by pulling ambient air and circulating it through the oven, which helps distribute heat more evenly. This is especially important in large ovens where the distance between the heating source and the material being processed can cause uneven heat distribution. Uneven heating may cause the material to warp, crack, or other defects, which may compromise the material's performance or integrity.

Heat treatment furnaces are widely used in various industrial applications to achieve certain material properties such as hardness, strength and durability. The process involves exposing the material to high temperatures, which can reach thousands of degrees Celsius, over a period of time. Ovens are designed to provide a controlled heating environment, but there are factors that can affect the uniformity of heat distribution within the oven. One of these factors is the air circulation inside the oven, which can be improved by the use of circulation fans.

There are many benefits to using circulation fans in heat treatment furnaces. First, they increase the efficiency of the furnace by reducing the time required to reach the desired temperature. This is because fans help distribute heat more evenly throughout the oven, meaning the material being treated can be exposed to the desired temperature more quickly. This can result in significant energy savings as less time and energy is required to heat the oven.

In addition to improving energy efficiency, circulation fans can also help reduce processing times. This is because they allow the oven to reach more uniform temperatures, meaning the material being processed can be exposed to the desired temperature for a shorter period of time. This can provide faster processing times, increasing productivity and reducing production costs.

Another benefit of using circulation fans in heat treatment furnaces is that they can help improve the quality of the material being processed. This is because fans help distribute heat more evenly, reducing the chance of material defects such as warping, cracking, or distortion. This results in a higher quality final product, which can lead to increased customer satisfaction and repeat business.

Finally, the use of circulation fans in heat treatment furnaces can improve worker safety. Because fans can help reduce hot spots inside the oven, which can help prevent accidents such as burns or fire. Additionally, a more uniform temperature distribution within the oven can reduce the risk of material failures or explosions that could pose a safety risk to workers.

As a result, the use of circulation fans in heat treatment furnaces can provide numerous benefits to industrial applications. These benefits include improved energy efficiency, faster processing times, higher quality end products and improved worker safety. Therefore, the use of circulation fans is an important consideration for any industrial application involving heat treatment.

+90 232 436 37 42

+90 534 225 75 11

info@vizyonheat.com.tr

Heat Treatment Furnaces

Heat Treatment Furnaces