Phone

+90 232 436 37 42

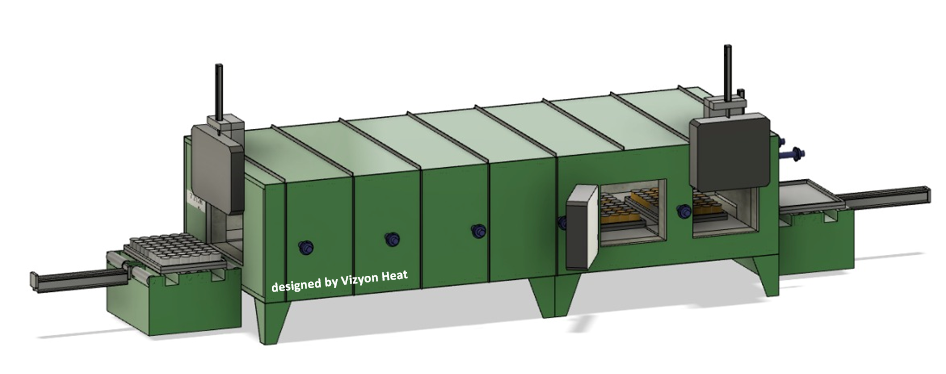

Pusher Furnaces are generally widely used in the forging industry. They can perform processes such as heating, preheating, tempering, annealing and stress relieving of the parts before the forging process. In these furnaces, how much material is used and at what weight, in what atmosphere it will be processed and the heat treatment temperature are important. Electricity or natural gas can be used as heating method.

The surface on which pushing will be done is generally designed as wear-resistant plates. As heat treatment furnaces, they have a design in which work flows continuously. Details such as temperature, heating method, and fixturing are determined according to the logic of the heat treatment process. Thrust force is usually provided by a hydraulic piston selected according to the force needed. Again, according to need, thermocouples are placed in appropriate places in the heat treatment furnace. Open flame burners are frequently used in such furnaces. The covers where the work enters and exits, safety covers, and the covers from which the fixtures are removed are determined according to customer needs. If necessary, the oil reservoir can be positioned at the end of the furnace for rapid cooling of the parts. The power of the burner or resistors must be determined according to the selected temperature and the mass of the parts. Appropriate insulation materials must be selected and applied expertly inside the oven for long-lasting use. Cover mechanisms must be long-lasting and provide the necessary insulation. The design of the door mechanisms is important to prevent the oven from malfunctioning. The furnace components are completed by automation of the appropriate electrical line and control system. As Vizyon Heat, we design and manufacture pusher furnaces for the forging industry.

+90 232 436 37 42

+90 534 225 75 11

info@vizyonheat.com.tr

Automation

Automation