Phone

+90 232 436 37 42

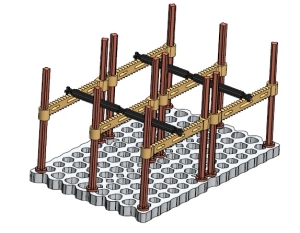

Ancillary equipment and spare parts of the heat treatment process are used at various points in the heat treatment process. The most common of these are furnace baskets used to load parts, furnace fixtures, part-specific heat treatment fixtures, graphite and CFC plates, and furnace baskets. Oven fixtures must be suitable for the type of parts, temperature and atmosphere of the environment. It can be produced by casting or welded manufacturing, and sometimes it can be manufactured from graphite, silicon carbide or alumina-containing materials or their composites.

In some cases, parts can also be produced in special geometries. Because under the influence of heat, materials may warp or go out of measurement tolerances. In these cases, fixtures produced in a special geometry with similar expansion properties as the part can be used. In some other examples, different furnace fixture designs can be made for parts whose circularity or flatness needs to be improved. Thus, the parts can be obtained with the desired geometric properties after heat treatment.

Oven baskets are generally designed with steel grades of 310 and 35Ni25Cr. Apart from these, graphite and graphic-containing composites (e.g. CFC) can be used for special uses.

Fırın sepeti

Isıl işlem prosesinin yan ekipmanları ve yedek parçaları ile ilgili diğer örnekler vakum ölçer, oksijen ve karbon miktarını ölçen sayaçlar (oksijen sensörleri), sıcaklık ölçen ısılçiftler (termokupl), ısıtıcı elemanlar ve rezistanslar, izolasyon malzemeleri, cam elyaflar, refrakter tuğlalar, cam veya seramik esaslı elyaflardan üretilmiş özel battaniyeler, fırın arabaları, gaz akış panosu sistemleri, ısı değiştiricileri, TUS ve SAT gibi fırın homojenliği ve sensör sapması ölçümünde kullanılan ölçüm sistemleri, kaçak cihazları, sertlik ölçerler, yağ banyoları ve yıkama makineleridir.

Gaz akış panosu

All these ancillary equipment are important for the heat treatment process to be fast, practical and repeatable, and their designs require attention. Well-designed ancillary equipment ensures that the process progresses faster and smoothly. Because how the materials and designs used will react in different temperatures and atmospheres must be determined by experts in a way that is as cost-effective as possible. Correctly selected spare parts ensure efficiency from the equipment.

In summary, heat treatment ancillary equipment constitute important components of the heat treatment process. As Vizyon Heat, you can contact us about the ancillary equipment and spare parts you may need in your heat treatment process.

+90 232 436 37 42

+90 534 225 75 11

info@vizyonheat.com.tr

Circulation Fan

Circulation Fan